教室建設 2015

Classroom construction 2015

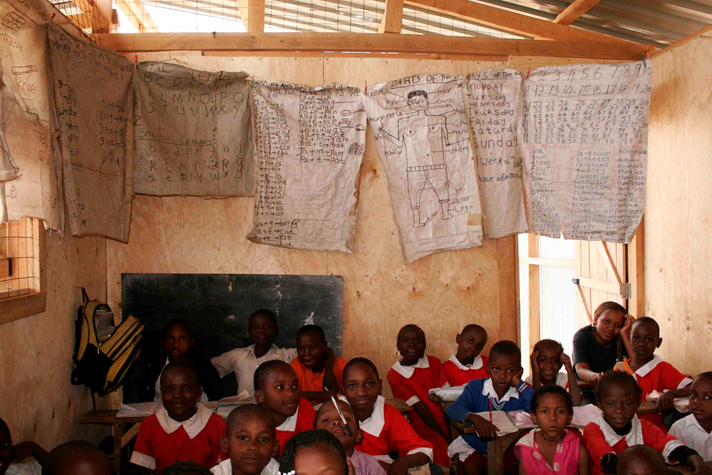

完成間近の教室/Almost completed classrooms

完成間近の教室/Almost completed classrooms2015年8月に小学校「Happy Promotion Centre」の教室2室+半屋外テラスを設計・施工を行った。

In August 2015, we designed and built two classrooms and a semi-outside terrace of the elementary school called Happy Promotion Center.

Happy Promotion Centreは2009年にMukuru Kwa Reubenに立ち上げられたノンフォーマルスクールで、当初は教師の自宅で、次に地域の集会所を間借りして運営がされていた。

子どもの数の増加に伴い、学校経営者がMukuru kwa Njengaに新たに土地を取得し、教室を建設することになった。ムクルでの土地の価格は、土地の面積ではなくそこにいくつ「部屋」が建設できるかで決められる。「部屋」とは10×10フィート(約3×3メートル)に規格化された賃貸住宅の1室を指す。学校が取得したのは5つの部屋が建設できるサイズの土地であった。

Happy Promotion Center is a non-formal school originally founded at Mukuru Kwa Reuben in 2009. Classes were held initially at a teacher’s house, then at a local community hall. As the number of students had increased, the school owner decided to acquire a new plot at Mukuru Kwa Njenga and build classrooms. At Mukuru, a land price is calculated based on “how many rooms can be built”, instead of the area of the land. In this case, “a room” indicates a standardized 10 ft by 10 ft room of rental houses. On the land the school acquired, five rooms could be built.

当時学校には幼稚園から小学校5年生までの子どもが40名弱在籍しており、教員は2名だった。学校運営者と話し、以下の方法で建設を行うことになった。

At that time, the school had almost 40 students, ranging from the kindergarten age to the fifth grade, and two teachers. We talked with the school operator and decided to build them in the following ways:

①学校側の能力に応じて時間をかけて教室を増築していく仕組みとすること/ Classrooms will be gradually added according to the capability of the school.

②現状、教員が2名であることから2室建設すること/ We start with two classrooms as there are two teachers.

③構造は、安価な木造とすること/ Their structure should be wood due to its low cost.

④基礎とスラブはコンクリートで施工すること(現地では基礎のない建物が多い)/Their foundation and floor slab should be installed with concrete. (Local buildings are often built without any foundation)

このうち、最初の2点は徐々に学校を成長させることで、建物をきちんと運営・活用してもらうためのコンセプトであり、後者の2点は、現地の状況を踏まえた必要最低限の建築スペックとし、コストを削減すると同時に、地域にとって異質な建物としないためのコンセプトである。

The first two points were measures to improve the school gradually and operate and utilize the building properly. The latter two were measures to choose minimum and suitable building specification, cut down the cost, and harmonize the new building into the local standard.

同エリアは、排水システムが整っておらず、雨季になると床上浸水は日常茶飯事である。路地もふくらはぎが埋まるまで浸水することもあり、小さな子どもは学校に通学できなくなるといった状況も見られる。今回建設する教室で最も重要だったのは、基礎とスラブをきちんとつくることで、これらの問題を解決することだった。その一方で、柱梁などの構造躯体は木造、壁や屋根は地域で一般に使われているトタンを利用した。これは現地でTemporary Structureと呼ばれる工法で、Permanent Structure(石造や鉄筋コンクリート造)と比べて劣った性能の建物という認識がなされている。

A drain system is not established well at this area, so inundation above a floor level happens on any day during the rainy season. An alley can also flood up to the calf level, which makes it difficult for small children to go to the school. What was most important for construction of these classrooms was making a proper foundation and floor slab with concrete, which could address the flooding issue. On the other hand, their structural frame such as columns and beams was wooden and their walls and roofs were made of galvanized iron sheet, the common building material of the neighborhood. Locally, buildings made in this construction method are called Temporary Structure, and regarded as lower quality buildings than what is called Permanent Structure made of stones and reinforced concrete.

しかしTemporary Structureはコストだけでなく、自力建設を行う上での施工性も高く、今後の改変性(増築、減築、移築)にも適していると考えた。Temporary Structureがもつデメリットである断熱性の低さについては、内壁を貼りダブルスキンとすることで対応した。

However, we considered that the Temporary Structure was more appropriate for this construction. In addition to its low construction cost, this construction method is easier for self build and more suitable for potential transformation of the building such as extension, reduction, and relocation. To address the low heat insulating property, the common disadvantage of the Temporary Structure, we added the secondary wall from inside.

基本設計は、日本で研究室の学生と共に行った。現地で2週間で、また自力で建設できることを前提とし、図面作成や構法、見積もりなどを作成した。現地では、学校運営者が周辺に居住する職人を中心としたチームを集め、リーダーとなる職人を中心に、地域の若者たちも簡単な施工を担当した。日本人も資材の買出し、資材運搬、掘削、木材の加工から、施工全般に参加しながら工程通りに作業は進んでいった。

電気が通っていないため、全て手作業で進める必要があり、また車が入ることのできない細い路地を通らないと建材の搬入ができず、最後は人力で運んだ。

Its general design was created in Japan with students of Imoto Laboratory. To self-build the classrooms in two weeks on the project site, we chose a construction method, created drawings, and quoted the cost. On the project site, the school operator created a construction team, mainly of skilled workers around the school.

A craftsman led the team, and some young people in the neighborhood joined in some simple installation works. Japanese staff also participated in many aspects of the installation, such as purchase and delivery of construction material, excavation, and timber processing. With the contribution of those people, the installation proceeded as it was planned. Due to lack of electricity supply, we had to do everything manually. We had to bring building materials through a narrow alley that a car cannot pass through, and carried them by hand.

予定を少し延長して3週間程度で教室は完成し、その1週間後には授業が開始された。新しい教室ができたことはすぐに地域に知れ渡り、さっそく近隣の子どもたちが30人程集まり、学校はそれまで挑戦できていなかった社会開発省から認定を受け、政府からオーソライズされるまでステップアップすることができた。

While the construction period was slightly extended, classrooms were completed in about three weeks, and the first class was held about a week later. Local people immediately found out that the new classrooms were built, and it didn’t take long to secure thirty students from the neighborhood. Later, by being acknowledged by the then Ministry of Social Development, the school improved its status to an authorized school.

日本で作成した教室のパース/Perspective image created in Japan

日本で作成した教室のパース/Perspective image created in Japan 授業の様子/During a class

授業の様子/During a class